By Jeff Bly and Parimal Kadakia, dB Control

RF/microwave components and integrated microwave subsystems serve numerous signal routing and conditioning purposes across a variety of applications, ranging from electronic warfare and directionfinding systems to radar cross-section and broadband test/measurement. Even though standard COTS components and assemblies are often ill-suited to meet evolving design and deadline requirements, some companies are still wary of custom products. This can stem from misconceptions about the cost, production time, or concern that a custom design is not field-proven.

dB Control addresses these concerns and delivers on performance by leveraging a collaborative, transparent working relationship with its customer’s system engineers. Our modular designs meet the most stringent system specifications without breaking the bank or missing deadlines. We use a three-step process to ensure success:

1. Prioritize Efficiency Parameters

Systems designers gauge the effectiveness of components and assemblies in terms of the design’s mechanical and electrical efficiency. Efficient mechanical design comprises fitting more functions into a smaller physical space (high-density integration). This is a key aspect of SWaP optimization and a long-running trend in the industry. Individual component demand has declined in favor of integrating multiple functions into one unit, contributing to efficient use of space and more efficient unit performance overall.

As for electrical efficiency, higher signal isolation and lower signal loss generally are system designers’ principal parameter concerns. But other specifications, including requirements for switching speed or power handling, must be balanced against the isolation and loss that can be achieved. Accordingly, custom component and subsystem design requires some back-and-forth communication between the vendor and its customers during the proposal and initial system test to ensure the custom component achieves the desired functionality at the system level.

dB Control works closely with each customer to pinpoint their system’s most important specifications and determine how to achieve them while maintaining other system parameters within an acceptable range. This bespoke approach has become a necessity, as system priorities and physical space for each unit vary from project to project, based on the application.

2. Provide Comprehensive Proposal/ Design

dB Control’s design process typically begins with the customer’s block diagram that details functions, layout, inputs/ outputs, etc. From this diagram, we gain an understanding of the customer’s requirements and then generate a proposal detailing our design approach to achieve their electrical and mechanical requirements.

Next, we assess the customer’s desired form factor, because that can steer a design from being planer or H frame to being stacked in multiple levels. Properly routing signals through different levels can be a complicated endeavor, but it is one in which we have a breadth of experience and expertise.

Finally, we consider volume. Production typically is scheduled out in reasonable quantities over a given period such that, as a manufacturer, we should not have a problem providing the customer’s requested volume. However, when the customer has a tight schedule that requires expediting the process, dB Control tracks all potential schedule risks to proactively manage them up front and prevent unnecessary delays.

If the customer deems the proposal acceptable, we progress to producing that design. If not, we work to improve it and deliver something closer to the customer’s request. The redesign process generally depends on the size of the teams involved and the timeframe, but it can include biweekly or monthly calls.

Ultimately, we try to match our customer’s sense of urgency. In most cases, customers are simultaneously dealing with other system design issues. When we provide them with the initial proposal, they must reconcile that data with the rest of the system. This generally takes longer than dB Control’s adjustment process.

Every time we provide a customer with an updated proposal/design, they must readdress how the changes fit with other components in the system. To build and maintain their confidence throughout the process, we can build a subset of the proposed hardware — the part of the design relevant to a specific parameter or other concern. Building that leg of the system enables us to provide live data we then can share with them. This onthe-spot evidence gives our customers the confidence in our proposed design solution and, by extension, that dB Control will be able to meet the unit’s overall specifications.

3. Use Modular Designs to Meet Critical Specs/Cost/Deadlines

dB Control provides components for a multitude of military, medical, instrumentation and telecom applications. This gives us experience working with numerous platforms and operating environments. It demands flexibility and adaptability not only in our designs, but in the thought processes used to generate those designs.

Our unique modular design approach enables us to:

- Integrate more functions into smaller and more form-constricted spaces than our competitors.

- Conceive, execute and manufacture custom RF/microwave components and integrated assemblies faster and more cost-efficiently than units created “from scratch.”

- Use similar modules to support multiple applications. This means we don’t have to completely redesign modules for every new assembly. In addition to design flexibility and timeline reduction, our modular approach minimizes materials cost because similar materials can be used in numerous applications.

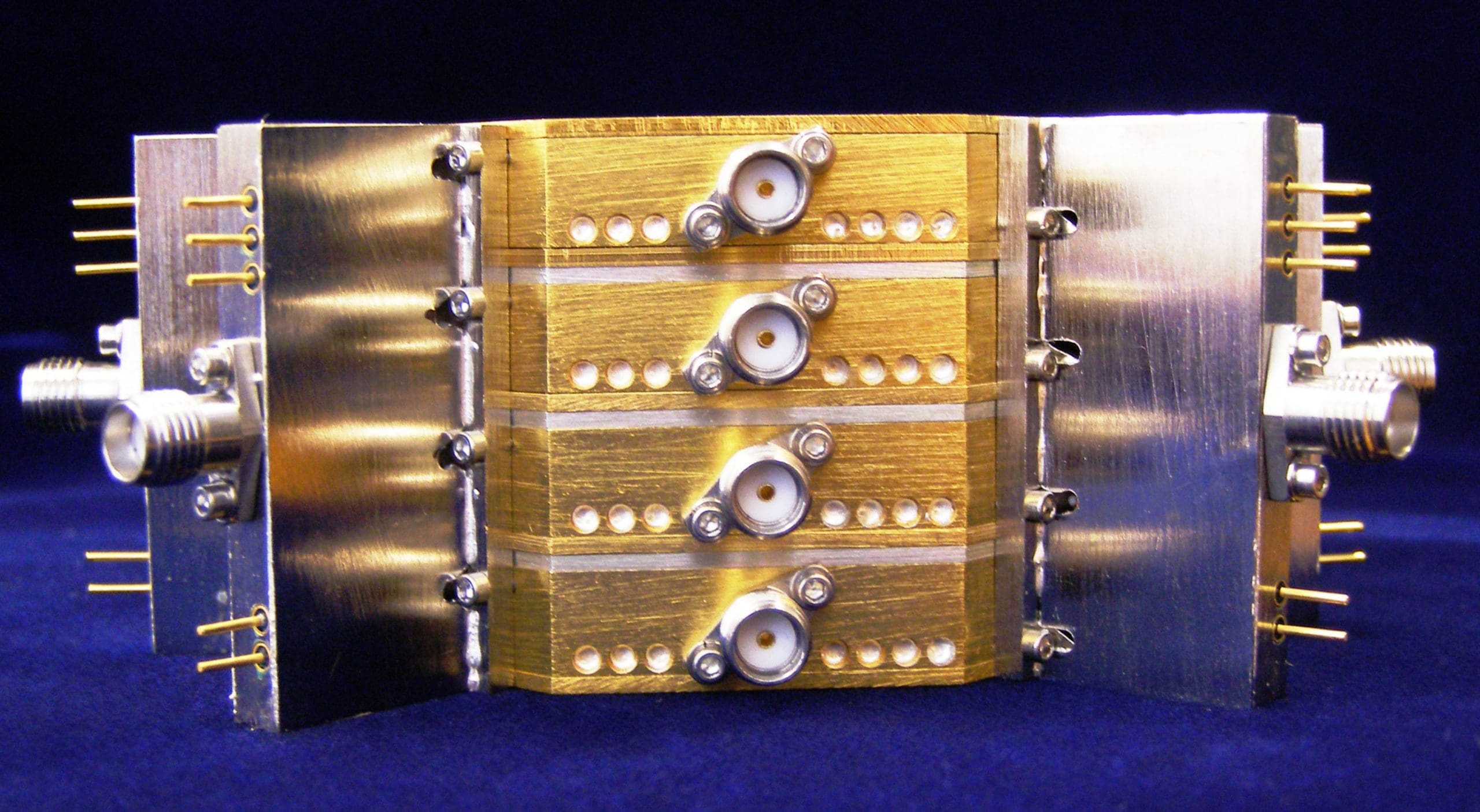

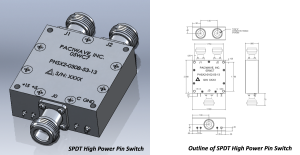

While technically many of the RF/ microwave components and subsystems we provide are custom, their creation is standard within dB Control. This enables us to be flexible, using modules available to us from similar designs (e.g., drivers, switches, analog control functions) and manipulate them to fit other layouts and formats. Such adaptability means dB Control can offer, for example, 2 to 36 port switches, manage all the drivers required and package it to meet specific needs. We don’t force our customers to use a static layout.

This expertise drives performance and function integration in many of dB Control designs. Consider switching, for example. With high isolation and power handling requirements: crosstalk and similar problems such as spurs bleeding out throughout the system can confound vendors lacking the switching expertise to isolate signals. As most systems specs have spur requirements (e.g., minimum 60 dB or 80 dB down), ineptitude chasing the source of those spurs wastes time, or worse, results in failure to meet customer requirements.

Readily available commercial off-theshelf (COTS) components such as MMIC amplifiers, filters or MMIC switches have limited performance. When integrated, there is little tuning flexibility to meet tough system requirements. However, many improvements can be made while integrating these individual functions along with carefully selected discrete device designs and carefully aligning them to provide additional tuning options. The result is excellent functionality for a system.

Summary

Organizations in need of RF/microwave components and microwave subsystems often have difficulty identifying standard catalog solutions that will perform optimally, or even fit adequately, within their specific systems. dB Control works with each customer to balance their design requirements with cost and performance trade-offs, producing custom layouts that adhere to their specifications.

We achieve this by utilizing a fielded, MilQualified modular design approach that enables increased flexibility to achieve challenging requirements, combining proven designs with intuitive customization that optimizes SWaP. To learn more, visit https://www.dbcontrol.com/products/#microwave.

About The Authors

Jeffrey Bly is the director of sales, custom products and components at dB Control. With 22 years of industry experience, he is a valuable resource for dB Control’s customers, including defense contractors and military organizations, that need custom RF/microwave components and integrated assemblies. Bly received his BSEE in Electrical Engineering from California State Polytechnic University.

Parimal Kadakia has more than 30 years of industry experience, including 20 years designing custom RF/microwave components and subsystems. He has resolved many design issues with his successful Paciwave product line, now part of dB Control. Kadakia holds a degree in Physics with a focus on Quantum Mechanics and Radio Communication.

About dB Control

Established in 1990, dB Control Corp., a subsidiary of HEICO Corp., supplies mission-critical, often sole-source, products worldwide to military organizations, major defense contractors and commercial manufacturers. The company designs and manufactures reliable high-power TWT Amplifiers (TWTAs), microwave power modules (MPMs), transmitters, and both low- and high-voltage power supplies with modulators for radar, electronic countermeasures (ECM) and communication applications. The company is ISO 9001:2015 certified. With the acquisition of Paciwave in 2021, dB Control now offers specialized RF/ microwave components and integrated microwave subsystems.