New Facility Increases Test Options, Improves Delivery Time, Accommodates Future Manufacturing Expansion

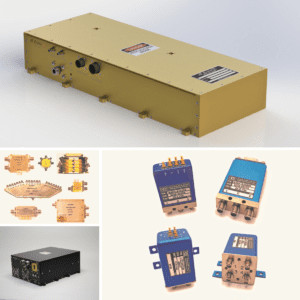

PRWeb – Fremont, Calif. – dB Control Corp., an established manufacturer known for its reliable, high-power microwave amplifiers, radar/electronic countermeasure (ECM) transmitters, and high- and low-voltage power supplies, is leasing an additional 12,100-square-foot facility adjacent to its main production facility in Fremont, Calif. The additional space at 910 Auburn Court, bringing the company’s total floor space to 52,100 square feet, will be primarily utilized to build out a new environmental test laboratory. The laboratory will enhance dB Control’s test capabilities by adding onsite Environmental Stress Screening (ESS), Highly Accelerated Life Test (HALT) and Highly Accelerated Stress Screening (HASS) services for its line of Traveling Wave Tube Amplifiers (TWTAs). In addition, the additional space will enable the company to accelerate production, eliminate outsourced testing fees and provide room for future expansion of manufacturing and assembly services.

The new laboratory will feature capital equipment and services, including:

- Temperature/altitude chambers

- HALT chamber

- HASS chamber

- Augmentation of existing shock/vibration equipment

- Modern network and signal analysis instrumentation

“Extensive testing ensures reliability – a non-negotiable attribute when it comes to systems used in military applications where lives are at stake. dB Control has a long-standing, industry-wide reputation for reliability. Expanding our internal test capabilities gives us more control over the processes, reduces costs and delivery time, and enhances our reputation as well,” said dB Control President Fred Ortiz.

The new laboratory enables dB Control to test final product in an automated 24-hour test cycle, thus reducing processing time and labor costs. Environmental chambers accommodate enclosures from small airborne to large rack-mount assemblies and can be programmed for custom combinations of temperature and altitude to match a mission’s profile. The vibration test capability allows testing at high G-force levels. To accommodate custom HALT/HASS reliability testing application profiles, high-temperature slew rates of 60˚C per minute can be combined with vibration testing levels of up to 60 gRMS, with six degrees of freedom for design margin testing. The new lab is expected to be fully operational in the third quarter of 2012.